Modern rail engineering’s view of efficiency and performance is much more comprehensive than just speed. Engineers are looking at rail components that are lighter, stiffer and more sustainable for high speed trains, metro systems and freight locomotives alike. Lightweight components can drive improvements across energy consumption, braking stability and overall lifecycle costs. How do we achieve lightweight components while maintaining structural integrity? This dilemma is an emerging strategic priority in the modern railway industry.

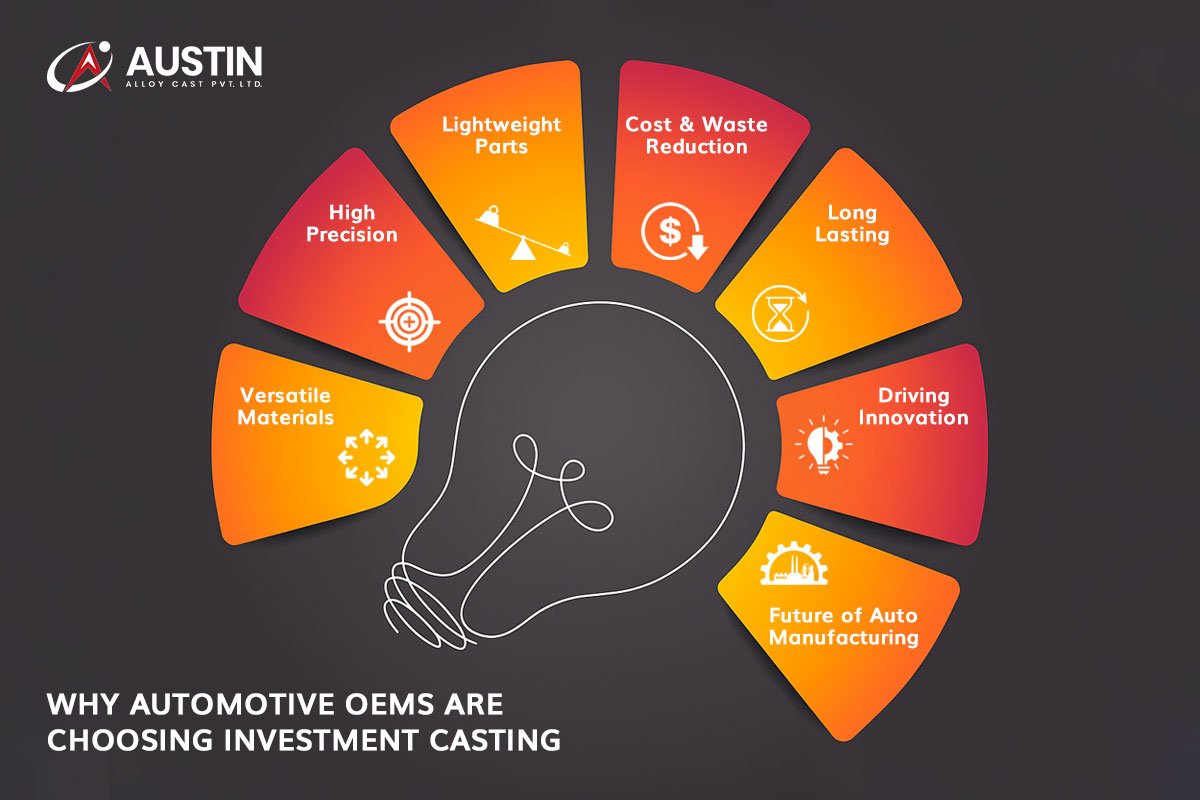

At Austin Alloy Cast, we argue that investment casting is the solution for this type of balanced engineering design. Through precision, material science and advanced process controls, investment casting will ultimately provide lightweight and durable components that can outperform traditionally manufactured rail components.

The Weight Strength Dilemma in Modern Railways

Lowering the weight of a train’s structure results in more fuel efficient trains and reduces the wear on tracks and wheels. However, strength, fatigue performance, and safety are essential criteria. Unlike automotive applications, railways operate in a more demanding environment and experience wheels and rail deformation due to constant vibration, load cycles, and environmental conditions. Mechanical performance is imperative for every component within the rail vehicle, whether it is a bogie frame, brake housing, coupling, or suspension component.

In traditional manufacturing methods, including forging or sand casting, weight is more difficult to control. Traditional manufacturing results in heavier designs due to lower dimensional precision and excessive machining allowances. Investment casting distinguishes itself from conventional manufacturing due to extreme tolerancing, geometrical complexity, and optimized weight to strength ratios.

Why is Investment Casting Suited to Rail Components

Investment casting also referred to as lost wax casting creates near net shapes with excellent dimensional control. To create the desired part, a wax pattern of the part is created, a ceramic shell, or investment, is applied to the pattern, the wax is melted out, and then molten metal is poured into the investment to form the final part.

There are several aspects of this high precision process that provide benefits for rail components:

- Design of lightweight: Create complicated shapes, hollow sections and thin wall thicknesses without compromising strength.

- Excellent surface finish: Significantly reduces heavy machining resulting in further weight savings.

- Dimensional consistency: Perfect fitment for safety critical assemblies like coupling systems and bogie brackets.

- Optimized material usage: Limit any excess metal, and loads are optimized for strength to weight ratio.

Austin Alloy Cast is proud to customize this processing method to give the exact combination of mechanical performance, weight savings and design flexibility the railway engineer requires.

Creating Strength from Design and Material Selection

Any time in a weight reduction approach, there is more than just subtracting material; it is also about placing material. Austin’s engineering team works closely with rail designers to improve load paths, minimize cross sections and include structural options like ribs, fillets and reinforcing geometry. These minor improvements in geometry through investment casting yields a better strength to weight ratio than forged or machined equivalent.

Material selection is just as essential. At Austin, the best options for each rail application include a variety of optimized carbon steels, stainless steels, and nickel alloys:

- High carbon and very low alloy steels: The highest strength range in brackets, couplers, or underframe components where maximum toughness is essential.

- Austenitic stainless steels: The best combination of corrosion resistance, and fatigue strength are essential for rail projects that are exposed or in marine environments.

- Precipitation hardened and nickel-based alloys: The ultimate combination of toughness, thermal stability, and wear resistant for premium rail systems.

Austin can ensure each alloy is tailored to meet the necessary mechanical and environmental performance of its intended use through precise control of chemical composition, heat treatment and microstructure evaluations.

Case Examples: Strength thru Lightness

- Brake System Components: Investment cast stainless steel scales and housings reduce mass, without reliant performance characteristics; improving overall system performance responsively.

- Coupler and Suspension Parts: Cast low alloy steels retain tensile strength, while reducing total component weight resulting in overall improved fuel consumption.

- Interior and Structural Fittings: Thin walled stainless steel fittings give durability needed in warranty specification, allowing for lighter train interiors and reduced vibration loads.

In all these applications, Austin Alloy Cast is committed to helping rail operators and OEMs achieve a meaningful balance of performance, reliability, and efficiency.

Sustainability and Energy Efficiency Advantages

Lightweight rail components provide reduction of operating costs, as well as directly assist entity goals to benefit the environment. Energy consumption, emissions, and track wear are all lower associated systems of a train’s mass.

Investment casting assists these sustainability metrics through:

- Reduction in raw material waste through nearing net shape manufacturing.

- Decreased energy input during machining and post processing.

- Improvement in longevity of part usage, limiting replacement frequency and overall lifecycle emissions.

The processes that are completed at Austin are designed for efficiency, repeatability, and environmental responsibility from energy efficient furnaces to recyclable wax or recycled ceramic materials.

With decades of expertise in metallurgy and on site capabilities, Austin Alloy Cast has developed the reputation of a leader in precision castings for rail and transport engineering. We incorporate modern simulation models, innovative melting processes, and testing protocols to manufacture cast components that always excel beyond industry standards.

Our philosophy is not just manufacturing it is collaborating. We work closely with customers to optimize part geometries, minimize cost, and design every kilogram of casting to achieve the maximum mechanical return.

With Austin Alloy Cast Pvt. Ltd you are getting more than precision metal you are getting engineering confidence knowing every part is designed and cast to be lighter, stronger, and smarter.

The Future of Lightweight Rail Engineering

The quest for energy efficiency in rail will still count on advanced manufacturing methodologies like investment casting. As trains become faster, smarter, and greener, the desire for preciseness, performance, and lightweight will continuously increase.

At Austin Alloy Cast, we are proud to join in that experience. By adding innovative casting technology with metallurgical design we are assisting our customers rewrite the rails of the future lightweight, durable, and sustainable.