Achieving high quality across massive casting runs isn’t merely helpful; it shapes how well products work, whether customers stay happy, and whether the company lasts. Sectors like cars, power systems, ships, factory gear, and tough construction work demand exact matches over and over. Hitting that mark without fail means following tight routines, using advanced tools, and double checking every detail again and again.

When it comes to making large numbers of cast parts, Austin Alloy Cast Pvt. Ltd stands out in India. This company uses tried and tested methods along with strong engineering practices to maintain steady quality throughout its production runs. Starting from choosing raw materials, each phase up to final checking follows a path focused on consistency, clear records, and meeting global industry rules.

In this article, we explore the core strategies to ensure consistent quality in bulk casting orders and how foundries can implement them effectively.

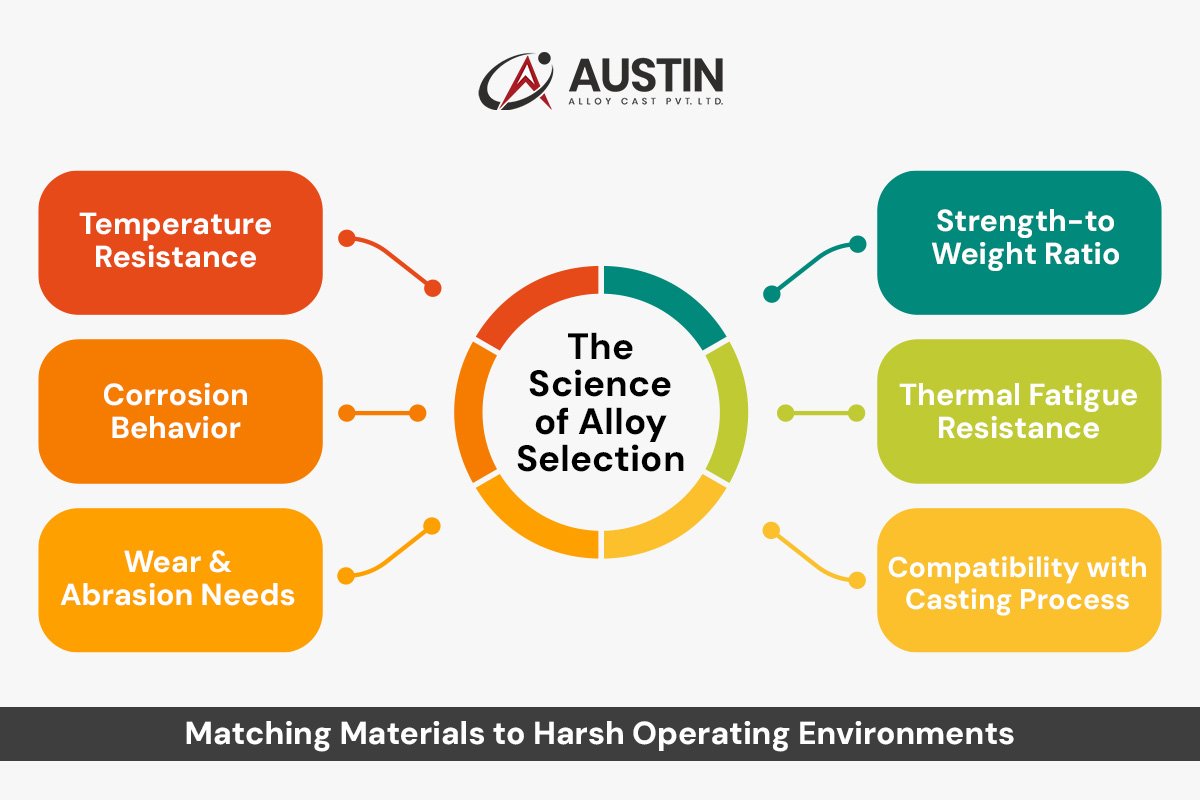

1. Select the Right Materials and Maintain Strict Alloy Control

The foundation of quality casting lies in material consistency. Even small variations in alloy composition can lead to significant differences in strength, wear resistance, corrosion performance, and dimensional stability.

Best practices include:

- Working with reputable material suppliers with documented traceability.

- Performing incoming chemical analysis and physical property testing for each batch.

- Maintaining accurate alloy documentation and certifications to ensure materials meet specifications.

At Austin Alloy Cast, we cast a wide range of materials from carbon and stainless steels to high performance alloys ensuring that each batch matches the specified chemistry and mechanical properties required by the application.

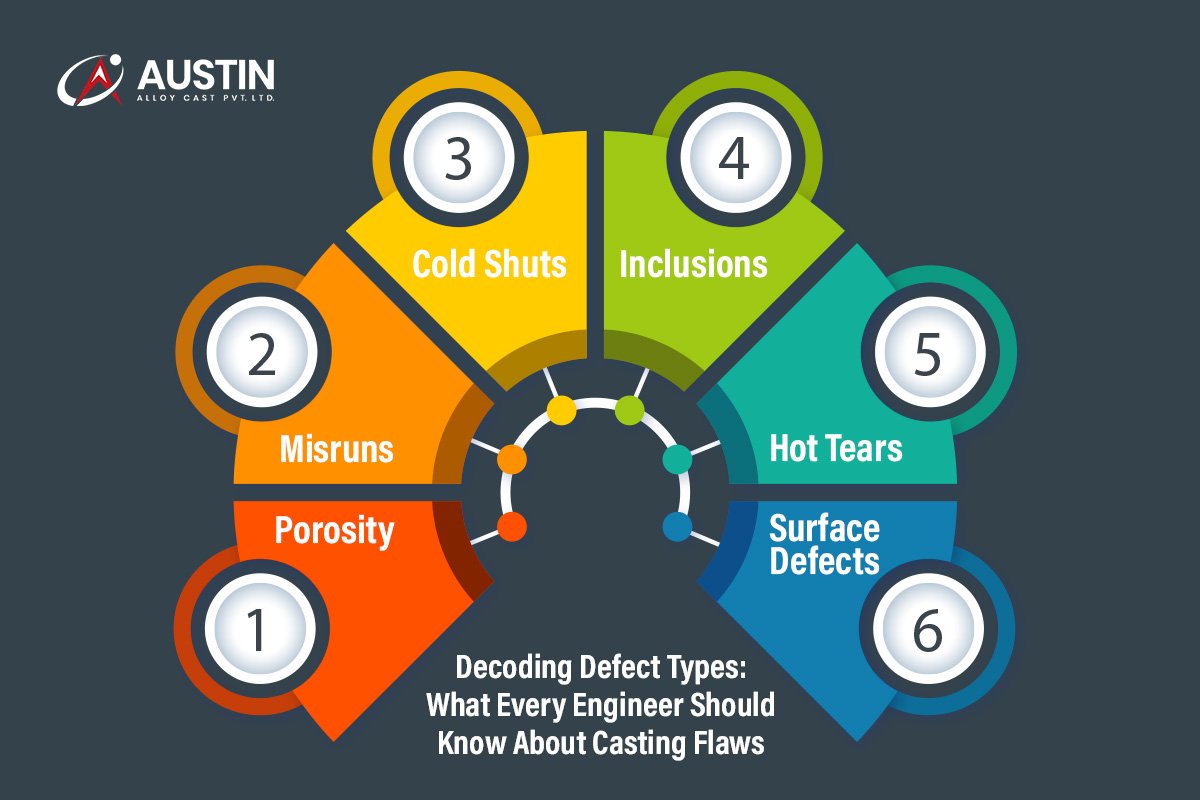

2. Use Advanced Process Engineering and Simulation Tools

Bulk orders often mean repeating a complex technical process hundreds or thousands of times. Variations in temperature, mold filling, solidification, or cooling can lead to defects such as misruns, porosity, shrinkage, or cold shuts if not properly controlled.

Modern foundries combat this by:

- Using 3D design and solidification simulation software to predict metal flow and cooling behavior.

- Optimizing gating and riser systems to promote uniform filling and reduce internal defects.

- Standardizing furnace temperatures, melt handling, and degassing procedures.

Simulation not only identifies potential trouble spots early, but when integrated with real world process controls, it enables consistent reproduction of high quality castings across bulk production runs, a core capability at our facility.

3. Maintain Precise Control Over Molding and Casting Parameters

The repeatability of a casting process is directly tied to how well mold making and pouring operations are controlled.

Key considerations include:

- Mold quality and maintenance: High precision ceramic or refractory molds with tight tolerances help achieve consistent dimensional accuracy.

- Temperature consistency: Monitoring and controlling melting, pouring, and cooling temperatures ensures metal properties remain uniform.

- Environmental control: Clean, temperature regulated workshops reduce the risk of contamination and defects associated with humidity or particulate matter.

Austin Alloy Cast’s investment casting process is engineered to ensure dimensional precision and surface finish consistency, enabling predictable performance even across large batches.

4. Implement Rigorous Quality Assurance Throughout the Production Cycle

Consistent quality is not a matter of inspecting finished parts alone; it’s about embedding quality throughout the entire production chain.

A robust QA framework should include:

- In process monitoring: Track critical parameters such as melt temperature, pouring rate, and cooling profiles.

- Non Destructive Testing (NDT): Techniques like radiography, ultrasonic testing, magnetic particle inspection, and dye penetrant tests help detect internal or surface defects without harming the part.

- Dimensional and mechanical testing: Coordinate Measuring Machines (CMM), hardness tests, and tensile testing ensure parts meet design tolerances and performance criteria.

- Documentation and traceability: Keeping detailed logs of raw materials, process parameters, quality checks, and inspections allows discrepancies to be pinpointed quickly and corrective actions implemented.

By integrating NDT into multiple production stages not just at the end, Austin Alloy Cast minimizes rework, reduces scrap rates, and assures customers that each casting complies with both design and regulatory standards.

5. Standardize Procedures and Train Skilled Operators

Consistency requires people as well as processes. Standard Operating Procedures (SOPs) should guide every step of casting production, from wax pattern preparation to shell building, pouring, heat treatment, and finishing.

Best practices include:

- Creating documented SOPs for each operation and regularly updating them based on process improvements.

- Establishing Statistical Process Control (SPC) charts to monitor key quality parameters and detect drift early.

- Training foundry staff and quality inspectors on the latest casting technology, inspection techniques, and quality standards.

Competent and well trained personnel are critical to interpreting data, executing processes reliably, and preventing inconsistencies that can compromise large orders.

6. Foster Continuous Improvement Through Feedback Loops

Bulk casting quality isn’t static; it evolves through continuous improvement.

Companies should:

- Analyse production data to identify patterns, defect trends, or equipment wear.

- Solicit feedback from customers to refine specifications and enhance product performance.

- Regularly review and revise quality plans, incorporating lessons learned from previous orders.

Quality management systems like ISO 9001 which Austin Alloy Cast adheres to help formalize this continuous improvement cycle and embed it into the company culture.

7. Partner With Foundries That Offer Integrated Services

Finally, partnering with a foundry that provides end to end capabilities can significantly improve quality consistency in bulk orders. Facilities that combine casting, machining, heat treatment, testing, and finishing under one roof reduce variability introduced by handoffs between vendors.

Austin Alloy Cast’s integrated model encompassing investment casting, heat treatment, CNC machining, and comprehensive testing ensures tight control over each step in the production lifecycle, delivering castings that are ready to use with minimal additional processing.

Conclusion: Consistent Quality Is the Sum of Excellent Components

Ensuring consistent quality in bulk casting orders is not a single action; it’s a strategic blend of material control, advanced process engineering, meticulous inspection, skilled people, and continuous improvement. By embedding these principles into every production stage, manufacturers can deliver reliable, repeatable cast components that meet even the most demanding industrial requirements.

At Austin Alloy Cast, we’ve built our reputation on this foundation from raw material selection to final inspection and delivery helping customers across the globe trust that their bulk casting orders are manufactured with precision, integrity, and unwavering quality.