A large portion of the machinery utilized in oil and gas extraction, gas processing, pipeline transportation and refining needs to be engineered and constructed to operate within some of the environments on Earth: extremely high pressure wells, exposure to corrosive fluids, severe temperatures, abrasive flow conditions and the cumulative mechanical strain, from continuous operation. Devices functioning in these environments need to be engineered and produced using materials possessing the property combinations to ensure dependable operation without failure, for prolonged durations.

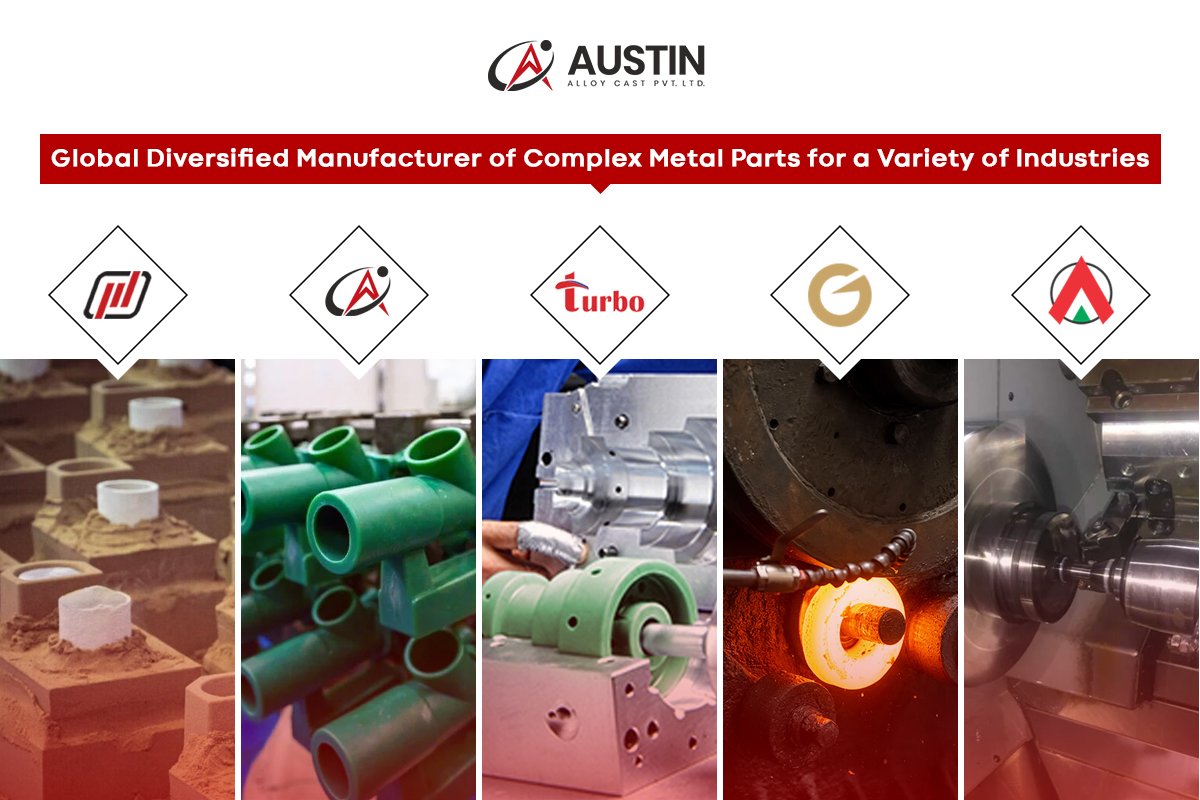

Consequently, investment casting technology has emerged as the favoured fabrication technique for creating high quality and precisely dimensioned parts in the upstream, midstream and downstream segments of the oil and gas industry. Components, for valves, pumps, drilling tools, instrumentation and flow control systems are some examples of castings manufactured using investment casting.

Austin Alloy Cast is presently, among the trusted providers delivering high quality parts for oil and gas OEMs worldwide.

High Performance Castings for Oil and Gas Valves and Pumps

Valves and pumps serve as elements in oil and gas activities. They ensure control over pressure regulate flow, prevent leaks and enable the transfer of fluids, within the production area. Valves and pumps require investment castings that will meet specific performance requirements, including:

- High resistance to both high pressure and temperature;

- corrosion resistance against sour gas, seawater, hydrocarbons, and chemical exposure;

- Smooth flow passages to achieve higher efficiency rates;

- Extremely tight tolerance control to achieve sealing accuracy; and

- Consistency of materials to provide long service life.

Expertise in Oil & Gas Valve and Pump Castings

Oil and gas are a core focus area for Austin Alloy Cast, accounting for more than 50% of the company’s total revenue, with a significant portion coming specifically from valve castings. This strong industry concentration reflects not only long term customer trust but also the company’s proven capability to meet the strict technical and quality demands of oil and gas applications.

Austin Alloy Cast has successfully executed large volume orders in exotic and high alloy grades such as CW6MC, CK3MCuN, and Stellite 6, materials that are widely used in critical valve and pump components exposed to high pressure, high temperature, corrosive media, and sour service conditions. Handling these alloys requires advanced metallurgical control, precise melting practices, and consistent process discipline capabilities that Austin Alloy Cast has developed and refined over years of experience.

With over three decades of combined knowledge in valve casting and machining fundamentals, the company understands not only how to cast complex valve bodies and components, but also how they behave during machining, assembly, and actual field operation. This deep application knowledge allows Austin Alloy Cast to deliver investment cast valve and pump components with reliable sealing surfaces, accurate tolerances, smooth internal flow paths, and long service life meeting the real world performance expectations of the oil and gas industry.

Common Valve & Pump Components

A large variety of oil and gas valves and pumps are produced with precision investment castings by Austin Alloy Cast:

- Valve Body Castings

- Bonnet Castings

- Impeller Castings

- Pump Casing Castings

- Seat & Disc Castings

- Gland Part Castings

- Stem Part Castings

- Flow Control Assemblies

Since they will be used in environments such as abrasive slurry, corrosive media, seawater from offshore drilling, drilling mud and high pressure applications, their cast materials and casting integrity will play a critical role in how well they will work in the field.

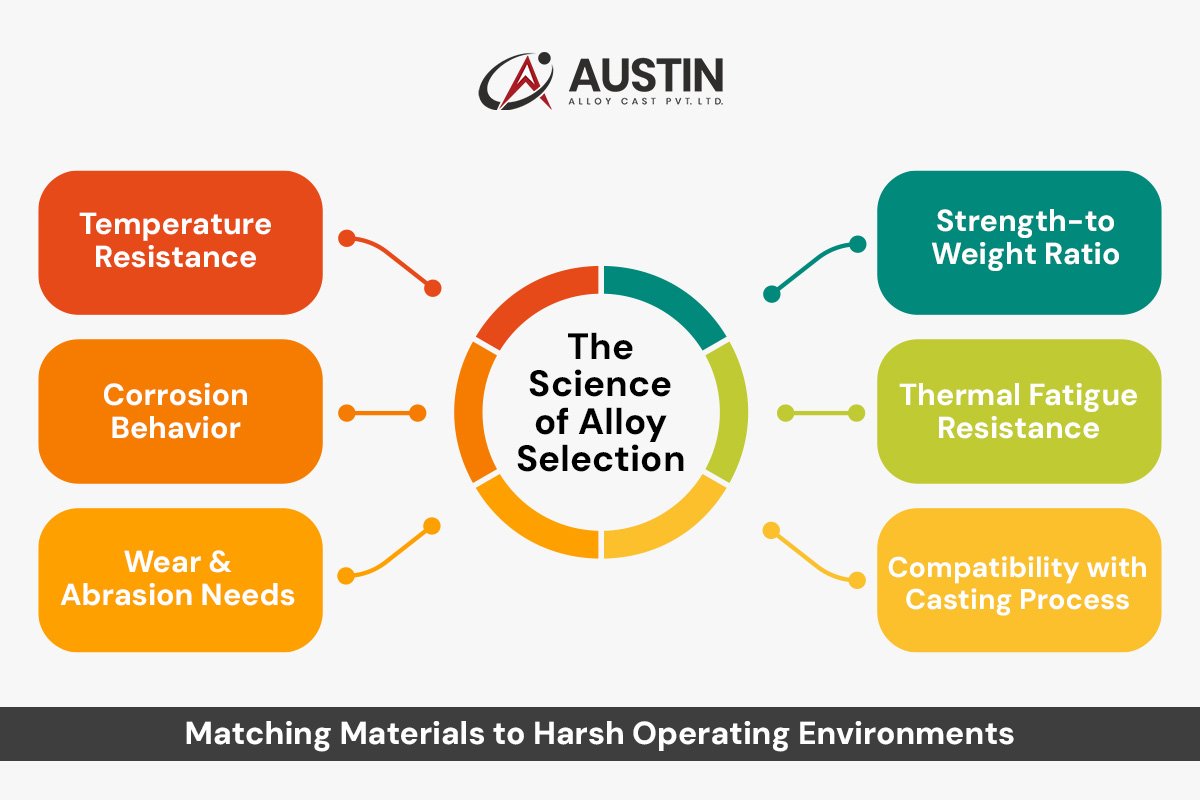

Austin Alloy Cast is an expert in the use of critical alloys designed to withstand the harsh operating conditions typically associated with the oil and gas industry.

Standard alloys are not acceptable for the production of equipment associated with the oil and gas industry, some of the things that components may be subjected to during operation would be, at the least, pitting, stress corrosion cracking, chloride attack, and mechanical load bearing.

Expertise in Critical Alloys

Austin Alloy Cast is well versed in the use of certain high performance alloy castings designed for other environments and industries:

Duplex Stainless Steel

Provides high strength and a considerably greater resistance to stress corrosion cracking and is best used for offshore and downhole parts.

Super Duplex Stainless Steel

Provides outstanding resistance to corrosion, particularly in seawater, brine, and chemical attack.

Inconel and Nickel Based Superalloys

Ideal for both high temperature and high pressure components used for refining and in petrochemical plants.

Cobalt Based Alloys

Cobalt based alloys, including Stellite grades, are selected for applications where wear resistance, erosion resistance, and hot hardness are essential. These alloys perform exceptionally well in valve trims, seats, and components exposed to abrasive media, high pressure, and elevated temperatures, making them critical for demanding oil and gas service conditions.

Heat Resistant Steel Grades

Excellent for the use as burner parts, furnace parts and other components that experience thermal cycling.

Therefore, by having a complete understanding of the materials that are being produced, Austin Alloy Cast is positioned to perform well in the production of components designed to perform, last and maintain safety in the operation of the oil and gas industry.

Complex Geometries

Investment Casting enables the formation of internal channels, shaped surfaces and, near net configurations that result in more efficient pumps and valves by generating smooth inner surfaces that minimize turbulence, energy loss and wear.

Austin Alloy Cast collaborates, with OEM engineering teams to produce:

- Walled parts that maintain a uniform thickness everywhere

- Precision surfaces to improve the dynamic properties of fluids

- Final forms requiring minimal, if any machining

- Parts that are cast as a piece to substitute fabricated or welded elements

Overall these features reduce the chance of leak failures. Extend the lifespan of a component by facilitating the efficient designs demanded by the industry.

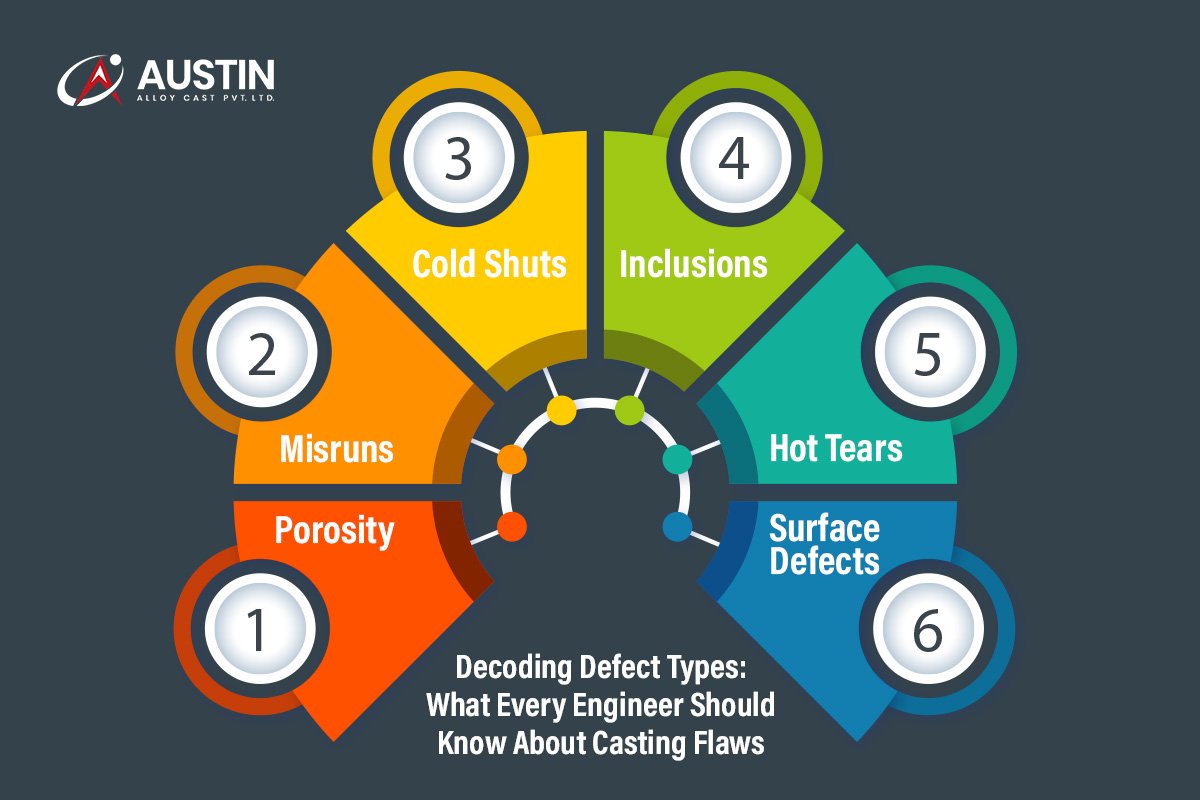

Strict Testing & Metallurgical Validation

In the oil and gas sector component malfunction is unacceptable. As a result every casting undergoes inspections and verifications such, as:

- Ultrasonic Testing

- Radiography

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Mechanical property testing of each casting.

- Chemical examination of every heat with complete material traceability.

These procedures are designed to verify that the components have excellent internal soundness, high strength, good ductility, hardness, and corrosion resistance. Austin Alloy Cast has developed a comprehensive quality management system so that all castings produced for offshore and onshore use are consistent with the same stringent requirements.

End to End Manufacturing

One of the major strengths of Austin Alloy Cast is its integrated manufacturing capability, which includes:

- Investment casting

- Heat treatment

- Precision Machining

- Surface finishing

- NDT inspection

- Final assembly support

For oil and gas OEMs, this translates into:

- Reduced sourcing lead time

- Lower logistic and vendor coordination effort

- Consistent quality across all stages

- Faster prototype to production transition

- Significant cost and time savings

This single source manufacturing model has made Austin Alloy Cast a preferred partner for global customers.

Trusted by Long Term Clients for Quality, Delivery & Engineering Support

Oil and gas projects often require customized castings, design improvements, or tooling modifications. Austin Alloy Cast supports clients through:

- Rapid prototyping

- Value engineering

- Input on material selection

- Simulation based casting design

- Long term production planning

Consistent quality, on time delivery, transparent communication, and a strong engineering backbone keep customers returning for long term partnerships.

Summary of key findings

Investment Casting is valuable for creating high performing and long lasting products for such applications as the oil & gas industry. Austin Alloy Cast provides reliable services in the production of these products, including valves, pumps and drilling equipment using Duplex, Super Duplex, Inconel and other high performance alloys.

Austin Alloy Cast has many capabilities; however, they combine all of these capabilities into one location to provide their clients with consistent Quality assurance (QA) and technical expertise. Therefore, Austin Alloy Cast offers reliable and performant products for OEMs in the oil and gas industry worldwide. As a result, when performance, safety, durability and engineering are critical to success, Austin Alloy Cast is the partner of choice globally.

Reach out to us for customer & project reference in oil & gas sector. We are proud to have contributed to some of the major project in the Downstream, Midstream, & Upstream. We will continue to support the future of energy.