The quality of an investment casting component is established earlier than many would think, as most people would assume. Before any metal is melted or poured, the wax injection process is the first step in producing precision castings. A wax pattern that is formed accurately will allow for proper dimensional accuracy, quality surface finish and produce “defect free” castings. A poor performing wax injection process can lead to multiple issues related to shrinkage, defect on the surface, cracks and/or dimensional deviation in the metal part.

At Austin Alloy Cast, the wax injection process is treated the same as other aspects of producing investment castings: through the application of control methods, which allows the team to ensure the wax patterns are manufactured precisely to customers’ specifications, allowing for reliable and repeatable high performance investment castings.

Why Wax Injection is Important:

The wax pattern acts as the “blueprint” for the final metal component produced by the investment casting process, as it is essentially a negative mold of the metal part. If there are inaccuracies in the wax pattern, it will be difficult to achieve the desired dimensional tolerances or surface quality of the finished castings.

The wax injection process may result in:

- Correctly shaped, uniformly sized wax patterns

- Excellent surface finish

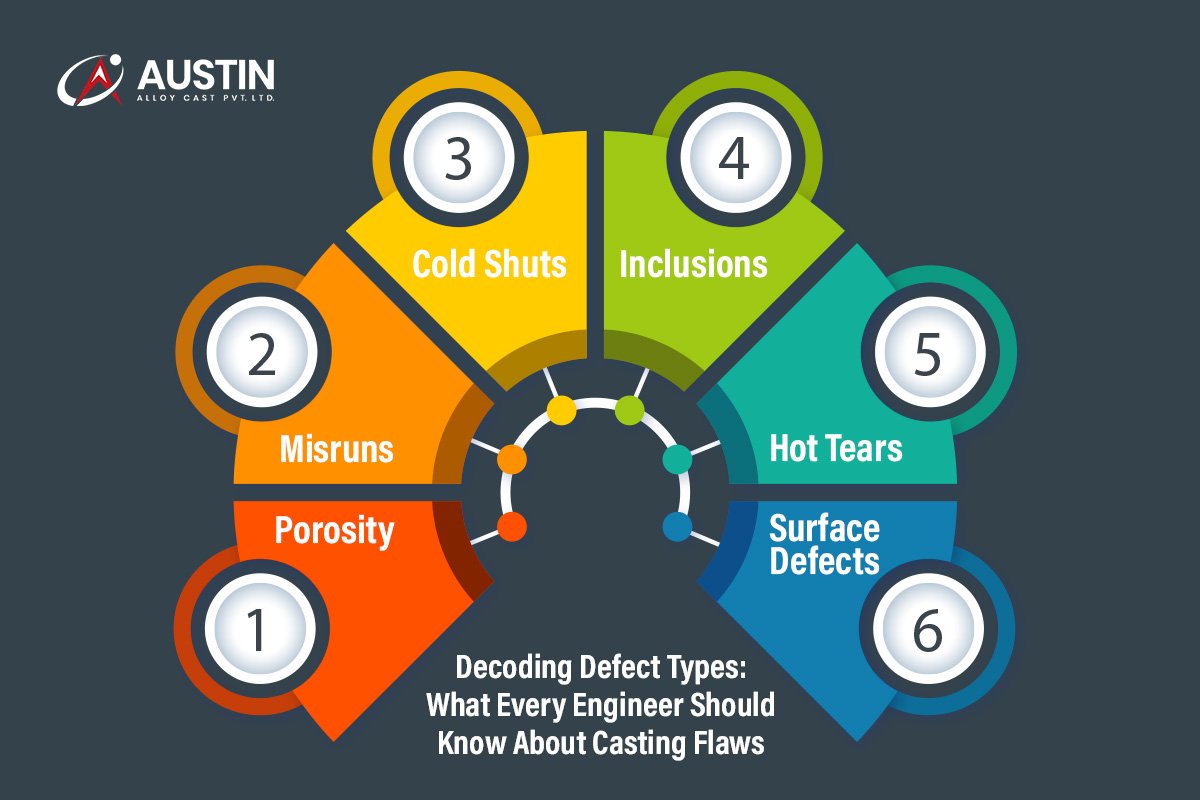

- Very few internal voids and porosity in the wax pattern

- Accurate filling of fine feature or complex geometries

- Extremely repeatable results across different batches

That is why Austin Alloy Cast invest so heavily in controlled wax injection systems!

Temperature: The First Critical Parameter

Wax temperature is paramount in determining how well the wax patterns flow, how much they shrink, and the quality of the surface finish of the wax patterns.

1. Wax Too Hot

- Flows excessively, causing flash and dimensional variation

- Increases shrinkage after cooling

- Can damage delicate areas of the mold

2. Wax Too Cold

- Leads to incomplete filling

- Causes cold shuts, surface roughness, and internal voids

- Results in weak patterns prone to breaking

The Importance of Proper Temperature Control at Austin Alloy Cast

Austin Alloy Cast uses an automated heating and monitoring system for maintaining consistent temperatures for each wax used based on the shape of the wax patterns and what type of material the mould is made from. This consistency of temperature reduces variability and provides increased repeatability in use.

Pressure: Ensuring Proper Mold Packing

Injection pressure is how well the molten wax fills the cavity of the mold. For thin sections, corners, or complicated detail, injection pressure is one of the determining elements for how well the wax fills.

If Pressure is Too Low

- Underfilled molds

- Cold weld lines

- Inaccurate reproduction of fine features

If Pressure is Too High

- Deformation or Distortion of the Mold

- Formation of Flash

- Increased stress within the wax pattern.

Austin Alloy Cast’s Method for Optimizing Pressure

Austin Alloy Cast uses calibrated injection machines that let them Easily set and adjust the injection pressure for each component. This is done through trial and simulation to find the proper pressure profile to use for Each part, so the mold is packed out fully without creating pressure and deformation.

Determining how the wax flows through the mold affects the overall quality product despite the temperature and pressure being set correctly .

Mold Filling Dynamics: Achieving Uniform Patterns

Even with correct temperature and pressure, how the wax flows inside the mould determines the final quality.

Key Mold Filling Factors

- Gate and vent design for smooth flow

- Mold material and rigidity to maintain dimensional stability

- Filling speed and cooling rate to prevent defects

- Air venting to avoid trapped gases

Austin Alloy Cast ensures each mould is engineered to promote smooth, turbulence free filling. Mold venting and gating are carefully designed to support uniform filling, preventing air entrapment and ensuring the wax reaches every detail.

Wax Injection Machines at Austin Alloy Cast

To support consistent, high quality wax patterns, Austin Alloy Cast operates a combination of manual and automatic wax injection presses, selected based on part complexity, production volume, and tooling requirements.

Classification of Wax Injection Machines

- Vertical Wax Injection Machines

These are manual injection presses, typically used for simpler geometries, lower production volumes, or tooling flexibility.

- Dual Wax Injection Machines

These are fully automatic wax injection presses equipped with top and side injection capabilities. Dual injection ensures uniform mold filling for complex geometries, thicker sections, and critical dimensional requirements. - Semi Automatic Wax Injection Machines

These are automatic presses with either top or side injection. Importantly, this type can be converted into a Dual Wax Injection configuration when required, making it part of the automatic press category.

Austin Alloy Cast’s wax injection setup includes machines ranging from 12-ton to 20-ton capacity. This mix enables the foundry to handle everything from small precision components to larger, more complex wax patterns.

How Austin Alloy Cast Achieves Consistent Wax Patterns

The wax injection process at Austin Alloy Cast is comprised of three distinct, yet closely interrelated components: technology, engineering, and artistry. Specifically, the wax injection process at Austin Alloy Cast has been developed through a combination of:

- Standardized temperature profiles

- CNC machined molds producing superior dimensional accuracy

- Optimized gating and venting configurations

- Automatic wax injection machines producing repeatable quality

- Skilled technicians who monitor/inspect each individual pattern

- Continuous research and development (i.e. wax behaviour, mold flow)

This integrated approach to wax injection ensures each wax pattern serves as a dependable foundation for the manufacture of investment castings that provide the highest possible precision and the highest quality of finish to support a wide variety of industries.

In conclusion, achieving the precise wax injection is no small accomplishment, and requires the strictest control of temperature, pressure and flow characteristics when filling molds with wax. By optimizing these parameters, a wax pattern becomes a perfect representation of the final metal casting.

The wax injection process is viewed as requiring the same amount of engineering rigor as does the process of melting, pouring, machining and inspecting metal. By mastering the science of the wax injection process, the Austin Alloy Cast consistently produces high tolerance, clean surfaced and reliable investment castings to satisfy the demands of industries requiring the highest quality and accuracy.