Futuristic general engineering implies improved productivity, smart functionality and sustainability. Precision casting of metal parts for general engineering is the process to make the parts with precise finishing. One can achieve accurate size and shape of engineering parts and excellent surface finish only with precision casting. These casted parts, in turn give shape to futuristic general engineering. As we are talking about precision casting, how can we not mention leading precision casting manufacturing companies? Austin Alloy Cast, which employs more than 250 employees at the world class foundry set-up back in India is one of the prominent manufacturers.

Why choose only precision casting?

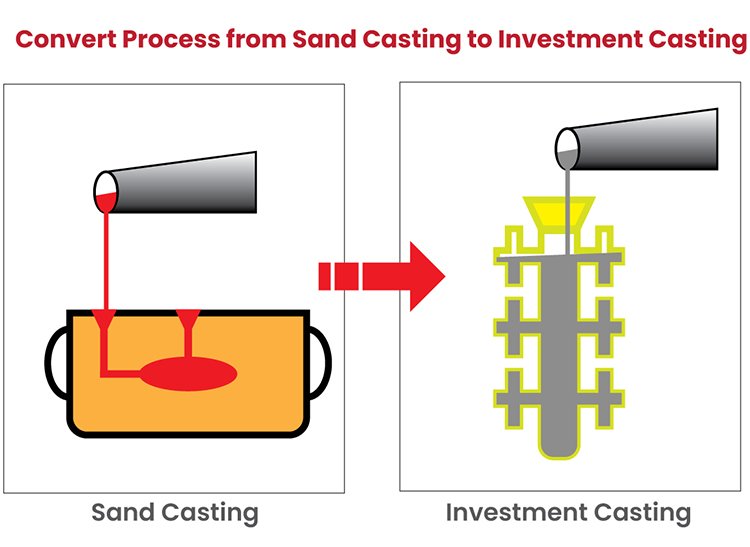

As mentioned above futuristic general engineering will be more advanced with smart functionality and improved productivity. Finishing quality of the metal parts used in general engineering is the crucial matter. Having blemishes, defects, porosity, uneven or unfinished surfaces in your metal components can lead to impaired productivity. Precision casting or investment casting process produces metal parts with excellent surface finish. Moreover, precision casted parts are visually appealing and look better than any parts manufactured using other processes.

Apart from finishing quality, precision casting can handle complex shapes of the components which are used for general engineering.

For all the reasons one should choose precision casting for manufacturing of general engineering metal parts or components. It is also important to choose the right foundry which can handle the process very well. Austin Alloy Cast offers a complete solution to manufacture your general engineering parts under one roof. Austin has expertise in gear blank casting, rope fitting components, marine transducer housing, rail coupler lock lift assembly, lantern, etc.

At Austin Alloy Cast, every project is handled with care and considering the requisites of it. If required technical consultation and value added services are offered.

Contact us on below given details to check availability and booking an appointment with our sales agent in your area.