In the changing environment of today’s manufacturing industry, the capacity to manufacture complex and engineered precision metal components will be a critical differentiator. Austin Alloy Cast is the prominent investment casting manufacturers trusted for their high level of technical capability, experienced foundry knowledge, and commitment to quality. The company’s ability to deliver complex metals casting geometries has created a global customer base across many industries, including automotive, energy, defense, and marine.

Recognizing the Issue: Why Complex Geometries Matter

Modern engineering designs call for components that are lighter, stronger, and more efficient all while holding tight tolerances in complex shapes. Some of these geometries may be thin walls, internal hollows, undercuts, and integrated features that are unsuitable for conventional manufacturing.

Investment casting or the lost wax process is ideal for these designs. While machining and fabrication often require multiple steps to achieve the shape, investment casting produces near net shape parts directly from a wax pattern. This decreases machining, reduces material waste, and yields consistency in dimensions and geometry even with complexity.

Austin Alloy Cast uses process control, advancements in technology, and metallurgic knowledge to recreate such complex components with superior consistency and quality.

Austin Alloy Cast: The Benefits of Engineering Complexity

As a premier investment casting company, Austin Alloy Cast has developed its processes to produce an unparalleled quality product. What makes the company successful in producing complex metal geometries is its operation of integrating modern technology, skilled craftworkers, and a disciplined quality control process.

Your Austin Alloy Cast experiences this by way of,

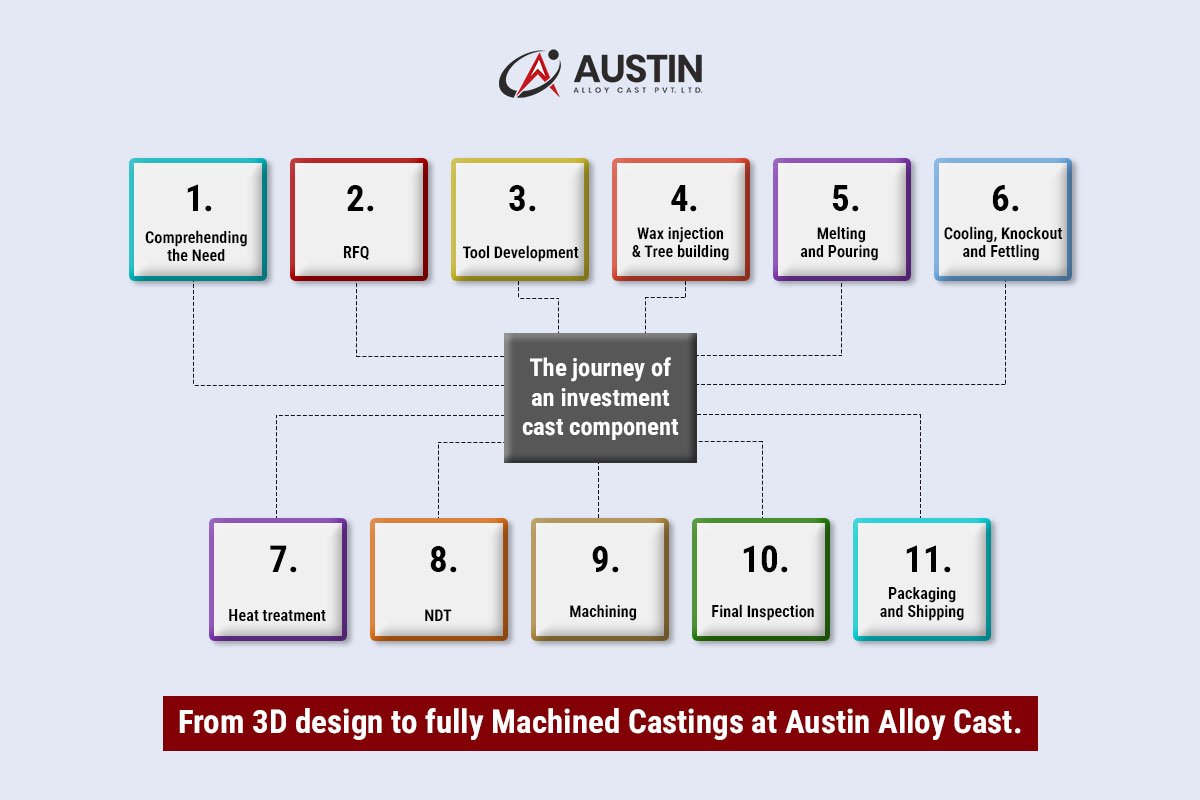

1.Advanced 3D Modelling and Simulation

Every successful casting starts with an accurate design. Austin Alloy Cast employs 3D CAD modelling, and solidification simulation software to formulate how molten metal will behave to flow, filling and solidifying in the mold. By modeling to simulate casting behavior, the engineers can detect and eliminate potential defects i.e. porosity, shrinkage, and distortion before the mold is made.

This potential validation measures that the delivered product will meet structural intergrity and dimensional accuracy for environmentally produced components that will experience high imposed loads.

2. Precision Wax Pattern Development

The investment casting process relies on the accuracy of the wax pattern which is an exact representation of the final part; whether complex or fragile, Austin Alloy Cast has automated wax injection and assembly systems that promote consistency in shape development. In most cases, the patterns are assembled into some multiple piece grouping called “treeing” to allow for multiple part casting and proven results in shortened operational times. Austin Alloy Cast has talented staff who assist with the overall inspection process that leads to patterns meeting requirement tolerances as even small mistakes matter in final castings achieving high levels of accuracy.

3. Quality Ceramic Shell Construction

It is vital that a durable and dimensionally accurate ceramic shell is created for both the complexity of the geometry being cast as well as the complex shapes. Austin Alloy Cast thoughtfully controls slurry coating, ensuring that the shell is constructed in a way that promotes adhesion of the layers to the wax model.

The shells are built in thin layers in a controlled environment and layering attaching in the drying of each of the layers. This creates a strong shell that holds better to high temperatures, providing the quality surface detail of the wax pattern being used for the investment process.

4. Metal Pouring Management and Alloy Capability

The reputation of the company relies not only on its control processes but also its metallurgy competency. Austin Alloy Cast is capable of producing parts in just about any alloy, specifically stainless steel casting, carbon steel and high temperature alloys.

A very strictly controlled, melting and pouring process including induction furnaces, temperature monitoring, and vacuum equipment ensures that molten metal fills every area of a sophisticated mold, which makes it easier to produce dense, quality castings with ideal engineering characteristics.

5. Machining and Finishing Precision

After the metal solidifies and the shell is taken off, castings have to go through a series of finishing processes, including shot blast, heat treatment, and CNC machining, which ensures that all the dimensional and surface finish requirements are met.

The machining division at Austin Alloy Cast is fully equipped with the latest tooling manufactured to micrometer specs. This leads to fully machined castings capable of being assembled or used in their final state, with reduced customer side processing time and overall lead time.

6. Rigorous Quality Control and Testing

With intricate metal geometries, controlling internal and external quality is critical. Some of the non destructive testing methods that Austin Alloy Cast utilizes include radiography, ultrasonic testing, magnetic particle inspection, and dye penetrant testing.

CMM inspection is also done to ensure dimensions are accurate; the company makes sure that every feature conforms to the 3D design model. It also implements ISO 9001, 14001, and 45001 for added emphasis on quality, safety, and environmental obligation.

Real World Applications: From Design to Delivery

The ability of Austin Alloy Cast to master complicated geometries has converted the company into a dependable partner for a number of industries.

- Automotive: Lightweight complex parts in fuel systems, turbochargers, and transmissions.

- Oil & Gas: Corrosion resistant stainless castings for valving, pumping, and flow control applications.

- Energy & Marine: Components designed to be durable and longer lasting in challenging environments.

In every case, the collaboration that Austin Alloy Cast has with customers during design and prototype development help to guarantee that the resulting product meets above and beyond the technical and economic expectations.

Innovation, Quality and Partnership

At its core, Austin Alloy Cast Pvt. Ltd. is more than just an investment casting manufacturer. It is a technical partner that brings engineering know how, cost effectiveness and metallurgical knowledge to help customers determine the right material and process for their application.

Austin Alloy Cast Pvt. Ltd. will continue to make investments in new technologies, automation and improvements, to push forward with an ever evolving industry. This process will ensure Austin Alloy Cast continues to remain well positioned to be a leader in innovation and a trusted supplier for manufacturers of complex metal components, with customers expecting precision and reliability to meet performance requirements.

Conclusion

When mastering complex geometries in metal casting, it truly is a choice of art and science experience, technology and diligence are only a few of the facts to the process. Austin Alloy Cast has a commitment to precision, process efficiency and partnered with its customers. In a short time, the organisation has been able to establish recognition across Canada as a trusted investment casting manufacturer that is capable of producing complex geometries into high performance stainless steel castings and other alloy components.