The greatest value addition we provide is our expertise to provide technical consultation for the most economical manufacturing/fabrication process. We have supported numerous customers for their process change projects from forgings, welded assemblies, sand castings to single Investment Cast component. Furthermore, our engineers understand the application of the component and can also suggest the best suited material grade. Be it any alloys of Steel ranging from Carbon Steel, Low Alloy Steel, Stainless Steel, Nickel based alloys and Cobalt based alloys, our Team can handle it with ease. We are able to extend this support because of A Lifetime of Experience in this Industry.

Design engineers are responsible for creating engineering equipment or product design which are efficient, non-destructive, durable and cost-effective for manufacturing. A Design engineer has to do a lot of research and work on prototypes. Best design is not about how it looks but also how it performs. High-end design engineers always strive for perfection in their designs. Affordability or cost savings comes second for them. But, companies still have pressure to make it cost effective and this pressure is passed onto the design engineers.

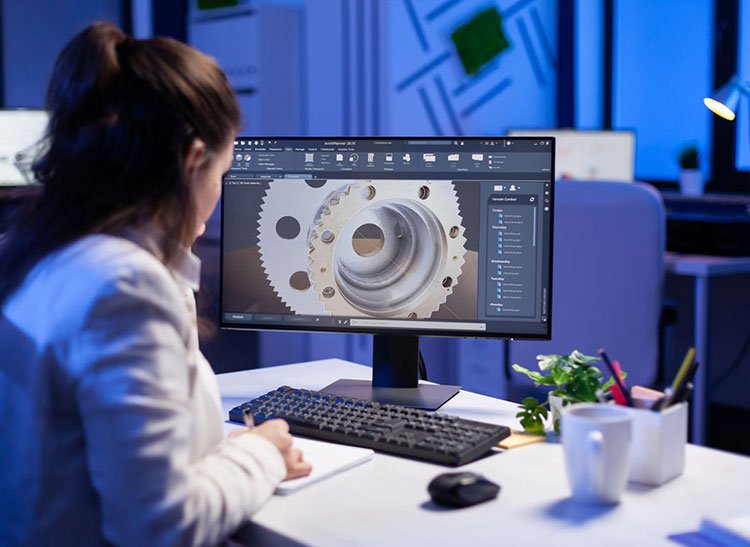

A design engineer can only be successful when they look at every aspect of product or equipment design with a detailed eye keeping in mind the end application of the part. It is very important that components used in engineering products are of high quality, perfect measurement and fits to the budget. Misfit components can destroy the whole design. Design engineers often coordinate with the procurement department for the purchase of quality and right configuration investment cast components required.

A role of product design engineers involve;

Do extensive research on raw materials/investment cast components to be used in the final products and the manufacturing process based on availability and price factors.

Create detailed sketches of the design on computer aided software.

Create Prototypes and test them on a real-time basis. If required re-create prototypes.

Once the design is ready, get feedback on the design and make sure it is efficient and non-destructive.

Good product designers also look into the manufacturing process of the component suppliers and if they use green or eco-friendly technology while doing research.

Austin Alloy Cast Pvt. Ltd. offers solutions for custom investment cast components demand which can help product designers create perfect designs. In our manufacturing process the energy we use is generated through solar panels – clean and green resources. Our in-house NDT testing facilities make you worry free about the quality of castings.

Design engineers in oil and gas, food processing, heavy and earth moving equipment, marine and general engineering industry can reach out at the details given below for more details.