Investment castings are a requirement of almost all the industries and so is the Oil and gas industry. Oil and gas industry is generally the backbone of any economy and counts in the billion-dollar industries list. Such an important industry largely depends on the components used in the machineries and ancillary processes.

Requisites for Oil and Gas industry processes:

The quality of the components used in the equipment is very crucial. Heavy duty equipment like valves, flow meter, liquid level gauge, flame arrestor, impellers, diffusers, bowl & support cage are used for each segment from downstream to upstream. Gathering and purifying raw gas, chemical injection, reciprocating, transmission and distribution processes have extreme levels of conditions. Various conditions like high pressure, chemical contact, weather or improper fitting of degraded components can adversely affect the overall plant. Degraded quality components may result in being corroded, crack-up, leakage or be smashed due to various extreme conditions. Standard grade components manufactured for the oil and gas industry are the requisites for any category process whether it’s upstream, midstream or downstream.

Investment casting manufacturer for High Quality components:

Investment casting manufacturers with experience and knowledge of the conditions at each process can produce standard grade components. Experienced investment casting manufacturers have understanding of the pressure level, guagage values, machine tolerance limit, chemical composition, etc. Knowledge itself is not enough to manufacture high-integrity components. Right infrastructure and technically sound, well experienced Team plays a crucial role in manufacturing of High Quality Steel and Stainless Investment Castings.

Austin Alloy Cast for technically advanced parts for oil and gas industry and timely delivery of the same:

Austin Alloy Cast Pvt. Ltd. is equipped with state-of-the-art infrastructure and facilities required for oil and gas investment castings. Testing lab, environment compliant manufacturing and ability to deliver in time makes Austin Alloy Cast leading supplier for investment casting components for European and North American oil and gas companies. What really sets us apart is our Team’s experience of handling a wide range of Steel alloys especially Nickel-based alloys and Duplex Steels.

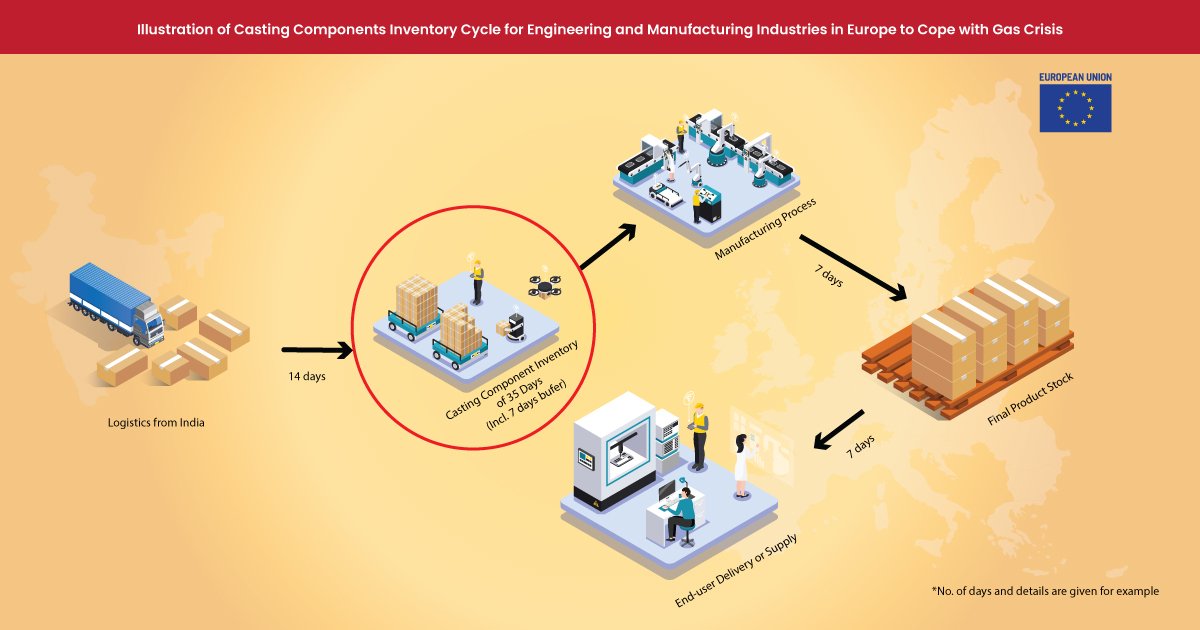

Gas crisis in Europe has created tension for foundries, their employees and customers. Due to gas crunch, many investment casting foundries and components manufacturers in Europe see the looming future of their businesses.

Gas crisis in Europe has created tension for foundries, their employees and customers. Due to gas crunch, many investment casting foundries and components manufacturers in Europe see the looming future of their businesses.