26 Feb 2026

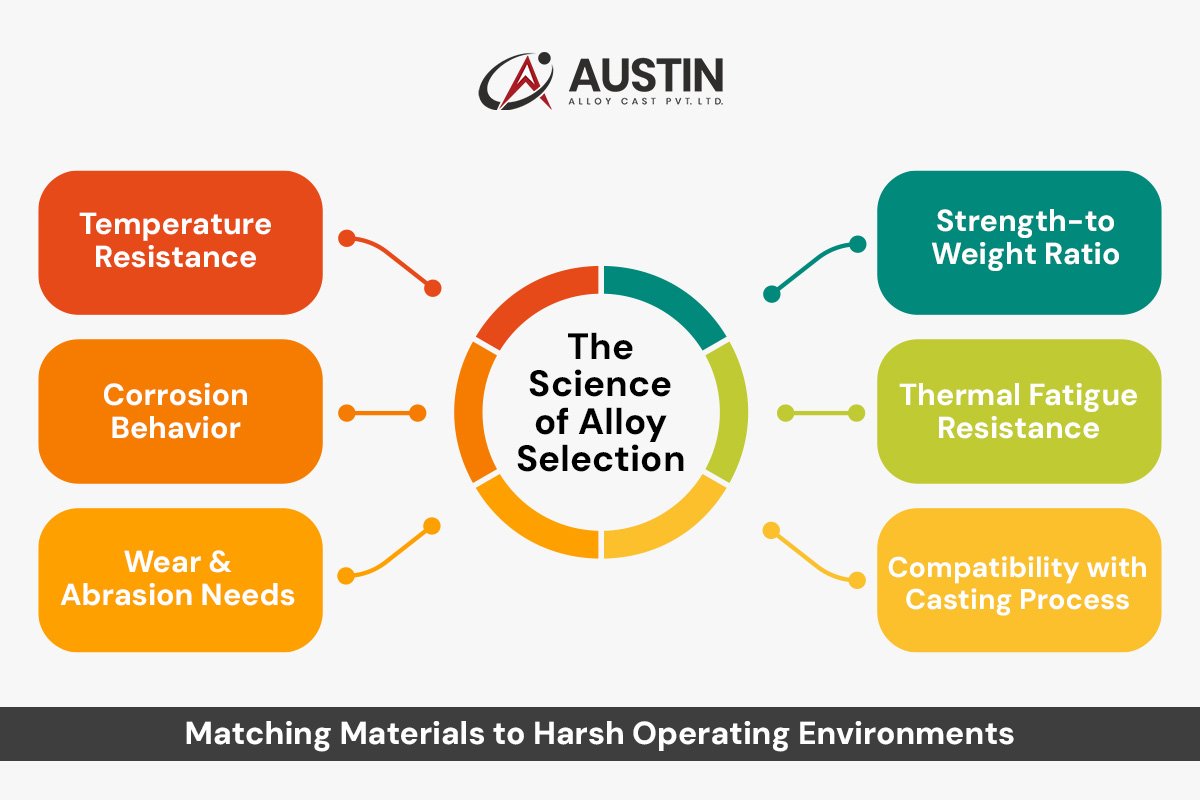

The composition of the material will determine the performance of the component. In industries that use parts which are subject to high temperatures, corrosive environments, mechanical abuse from constant wear and tear, or extreme duty cycles, the only way to provide an engineered component with a good performance level is by using an alloy based on a thorough scientific study to identify the appropriate alloy for the component. An alloy selection is not simply guesswork; the alloy choice is derived from a thorough scientific evaluation of the following performance requirements: expected performance requirements, potential operating conditions, casting behaviors, and expected long term reliability.

Austin Alloy Cast has developed a strategic methodology to identify the correct alloy for an engineered component based on years of metallurgical knowledge and practical experience. The alloy selection process also integrates the full understanding of how a given material will react to extreme environmental conditions when selecting an alloy. The balance of this article discusses these factors and provides insight into selecting the correct alloy for the engineered component you require.

Resistance to Temperature

The most basic inquiry regarding any application that puts metal through extreme conditions is whether the material will remain resistant to deformation, softening from heat, or losing strength.

When metals are heated to higher temperatures, their ability to be used as a structural member also decreases significantly; however, different types of alloys react to this increase in heat quite differently than one another. Carbon steels tend to lose structural integrity at much lower temperatures than stainless steels and nickel based alloys, which provide structural integrity under significantly higher temperatures than carbon steels are capable of withstanding, and thus when selecting alloys for equipment to operate in furnaces, exhaust systems, turbines and in equipment in petrochemical industries, it is extremely important to select the appropriate alloy as some alloys may soften, deform or creep under stress.

For the selection of alloys that have stable microstructures at high temperatures i.e., the use of austenitic stainless steels or nickel based superalloys gives the assurance that components remain dimensionally accurate and maintain their load bearing capacity after prolonged exposure to elevated heat. At Austin Alloy Cast, we assist our customers by recommending alloys that are stable in service by assessing and evaluating thermal stability curves, creep characteristics and compatibilities for heat treatment processes.

Physical and Chemical Ability

Corrosion is one of the highest level threats facing metals. It can happen from exposure to almost any medium including, but not limited to chemicals, moisture, salt water, oil and gas, and gases such as acidic fumes.

Corrosion causes metal loss over time, but it can also affect the strength of the metal, pollute products produced from it, and cause significant costs through failures. The addition of alloying elements such as chromium, nickel, molybdenum, and copper to a base metal improves the resistance of that alloy to corrosion by allowing stable passive layers to develop or improving the ability of the alloy to withstand pitting and crevice corrosion.

The use of alloys in the oil and gas, water treatment, marine engineering, and chemical processing industries must be evaluated carefully between their corrosion resistance and cost. The selection of alloys used by Austin Alloy Cast is made using a detailed chart of corrosion compatibility, along with the company’s experience with various alloy applications, to ensure the correct choice for corrosion resistance without sacrificing good overall quality and durability of the castings.

Wear Resistance and Abrasion Strength

A substance must be designed to endure the challenges of temperature and high friction uses. Various elements can affect a materials resistance to wear such as the toughness of the base alloy the microstructure of the cast pieces, the carbide content in the castings and the materials behavior, during heat treatment. When abrasion serves as the cause of failure for components, like pumps parts used in mining valve elements or rotating machinery a well engineered alloy can greatly extend the service life of the component before it needs to be replaced.

The materials listed below deliver performance, for such applications:

- Hard steels,

- High chromium irons,

- Cobalt based alloys,

- certain grades of nickel.

The reason these alloys perform so well is that they combine the High Hardness, Stable Carbide, and Superior Abrasive Resistance properties that make up the basis of wear resistance.

In designing a component, each engineer must factor the wear characteristics of the application whether they are going to be sliding, impact, erosion, or any combination thereof. In evaluating the wear characteristics of an application, Austin Alloy Cast will provide recommendations on the best alloys available and their optimal hardness, toughness, and microstructural stability to ensure that the castings will retain their surface integrity during continuous friction and particulate attack.

Strength to Weight Ratio

In many current industries performance is not only a measure of longer lasting durability or having a longer lifespan but also a measure of how well you are using your resources with a focus on making products as light in weight as possible while maintaining maximum effectiveness. Therefore, when looking at industries such as automotive, defense and energy, the strength and weight ratio has become a major factor in deciding which materials to use for applications where the overall performance is key i.e. every gram counts.

Several types of alloys e.g. high strength steel, aluminium bronze, titanium based, nickel alloys have been developed that provide considerable amounts of strength without adding excessive amounts of bulk to the product. Some examples of applications where an optimal strength to weight ratio could benefit are actuator, brackets, housing and rotating components.

Alloy recommendations made by Austin Alloy Cast not only take into account mechanical performance, but also take into account post manufacturing advantages associated with utilizing lightweight alloys instead of traditional heavier alloys that are generally less safe for users.

Resistance to Thermal Fatigue

Thermally Fatigue Resistant materials are required for components which undergo repeated cycles of heating and cooling. These thermal cycles cause internal stresses to accumulate and ultimately create conditions for thermal fatigue cracking if the material’s alloy is not stable.

Thermal Fatigue Resistant materials are necessary for applications like:

- Heat exchangers

- Turbocharger housings

- Furnace fixtures

- Power generation systems

Components produced for these applications must allow for adequate ductility, oxidation resistance, and resistance to microstructure degradation over time. Austenitic stainless steels, nickel based alloys and cobalt based systems are commonly used for their high resistance to thermal shock.

At Austin Alloy Cast, our use of simulation software and metallurgical testing helps us find the alloys that will remain structurally and mechanically sound after thousands of temperature cycles.

The Casting Process Compatibility

The most suitable alloy is not useful unless it is able to cast economically and consistently. In selecting an alloy, compatibility with the casting process should be considered in:

- Fluidity in the molten state

- Shrinkage characteristics

- Solidification patterns

- Tendency to develop porosity or hot tears

- Machinability after casting

Alloys behave differently when they are in the casting process. Some alloys require rapid solidification in order to not crack; while other alloys require more refined gating systems to allow for proper casting of the final product. Essentially, at Austin Alloy Cast, we specialize in Process Metallurgy, so that the selected alloys will perform as required, as well as flow, fill & solidify, in a predictable manner. This allows for dimensional accuracy with high integrity while casting.

The Importance of Alloy Selection

The choice of an alloy is much more than selecting an available metal, it is also a design choice that affects the lifespan of each component. Selecting the proper alloy reduces downtime, improves safety, increases component performance, and decreases the total cost to own the component.

Austin Alloy Cast offers decades of combined experience in the foundry industry, metallurgical knowledge and casting simulation technology to identify the appropriate alloy to suit the conditions in which it will be used. By analysing the temperature stress, corrosion potential, wear patterns, thermal fatigue properties and compatibility of castings, we verify that each component is manufactured to perform under the most adverse environmental conditions.

To have a glimpse at our world class facility and products, visit us at www.austinalloycast.com.

For any queries or details contact us at info@austinalloycast.com.