Benefit of Investment Casting

INVESTMENT CASTING SERVICE TO HELP YOUR BUSINESS MASS-PRODUCE COMPLEX, DETAILED METAL COMPONENTS.

Investment casting has several advantages over other methods such as sand casting and lost foam casting.

The enduring popularity of investment casting across five millennia speaks to its fundamental advantages, which remain relevant whether producing ancient bronze sculptures or contemporary aerospace components. The process offers a unique combination of capabilities that few other manufacturing methods can match.

Perhaps the most significant advantage is the ability to create extraordinarily complex geometries. Investment casting can produce parts with intricate external contours, internal passages, undercuts, and thin walls that would be prohibitively expensive or simply impossible to create through machining or other casting methods. Components that might require dozens of individual machined pieces assembled together can often be produced as a single investment casting, reducing assembly time, eliminating potential failure points, and decreasing overall weight.

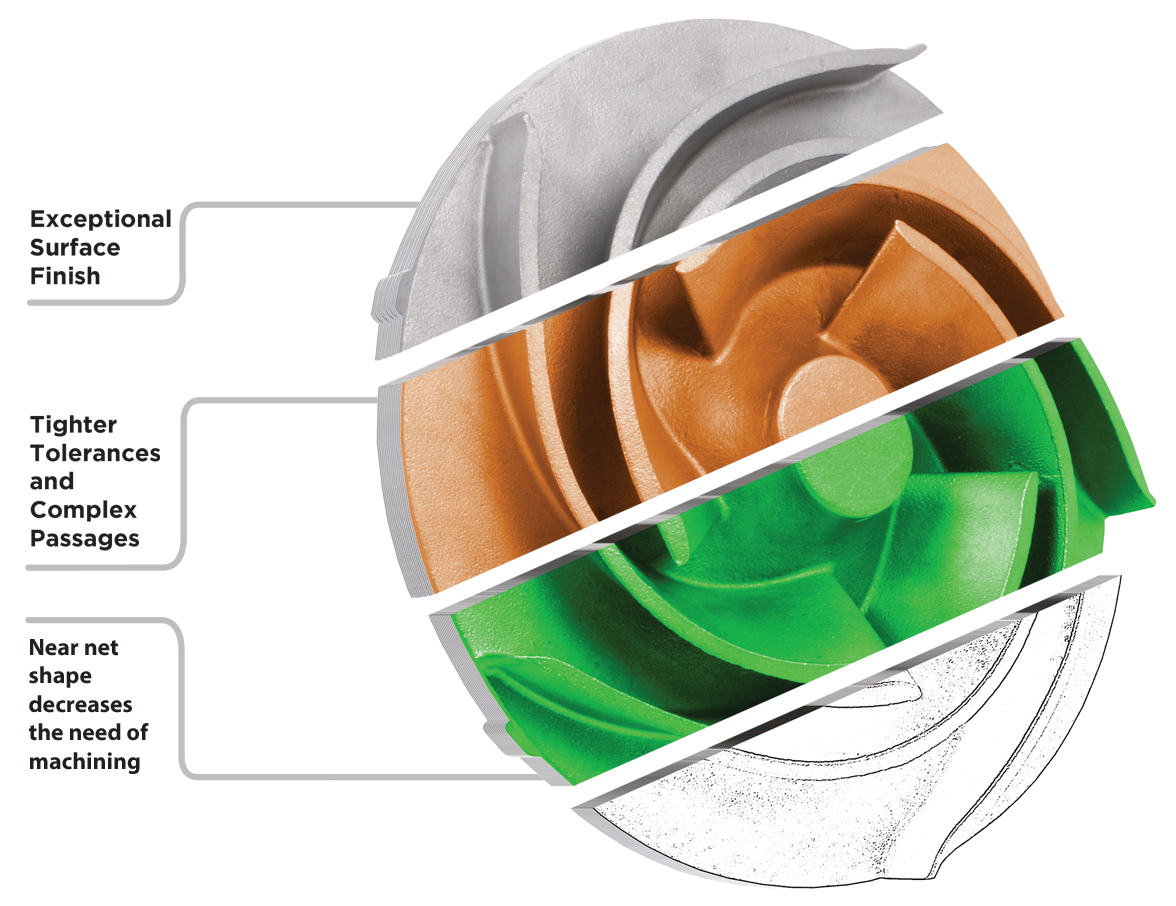

The surface finish achieved through investment casting is exceptional, typically ranging from 125 to 250 micro inches. This quality often eliminates or significantly reduces the need for secondary machining operations, saving both time and money while preserving material. The smooth surfaces are not merely cosmetic; they can improve aerodynamic performance, reduce stress concentrations, and enhance corrosion resistance.

Dimensional accuracy represents another critical advantage. Investment casting can routinely achieve tolerances of ±0.005 inches per inch, with even tighter tolerances possible for critical dimensions. This precision reduces the need for expensive post-casting machining and ensures consistent part-to-part quality, which is essential in applications where safety and reliability are paramount.

The versatility in material selection sets investment casting apart from many competing processes. Virtually any metal or alloy that can be melted and poured can be investment cast, including difficult-to-machine materials like titanium, cobalt-chromium alloys, stainless steels, and super alloys. This flexibility allows engineers to select the optimal material for each application without being constrained by manufacturing limitations.

From an economic and environmental perspective, investment casting excels at producing near-net-shape parts, meaning the cast component requires minimal additional material removal. This characteristic significantly reduces material waste compared to machining parts from solid stock, where much of the original material becomes chips. For exotic materials, this waste reduction translates directly into substantial cost savings. Additionally, investment casting becomes increasingly cost-effective for small to medium production runs where the flexibility and quality justify the tooling investment.