26 Feb 2026

Investment casting, a technique which is used to produce metal parts is a key development in process of manufacturing today. It plays a crucial role in production of dynamic metal parts that require direction, consistency, and sturdy materials. The industry that benefits most from this process is the marine industry.

Whether it is for navy ships, commercial vessels or offshore structures, the marine industry needs materials that can build structures which navigate through harsh environments, high pressure, and constant stress—without failing. Investment casting offers a reliable way to produce such high-quality parts.

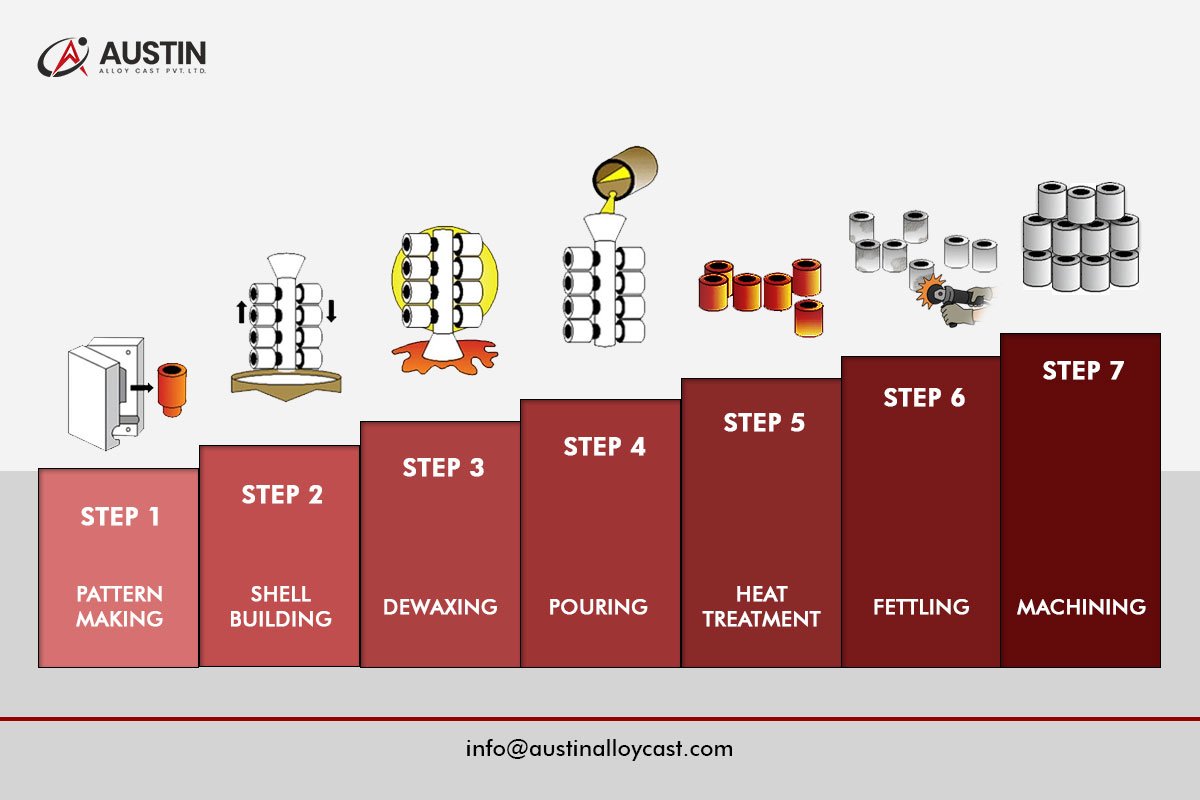

Let’s understand the process of investment casting in detail.

What is Investment Casting?

The process of Investment casting is quite complex in which a wax model is used to create a ceramic mould. After that molten remain is then poured into this mould. After its cooling and solidification, the ceramic shell is removed, leaving behind a finished metal part. This method is known for creating parts that are highly accurate and detailed, with ability to achieve near-net-shape finish.

Steps in the process:

Variety of Ferrous & Non-Ferrous materials can be casted via the Investment casting process, in order to get strong, smooth, and precise component perfect for use in tough marine conditions.

Challenges in the Marine Industry

The marine industry is one of the most demanding fields when it comes to equipment. Parts used in this industry must resist:

• Saltwater corrosion

• Wear from sand and sea particles

• Vibrations and stress

• High-pressure environments

• Temperature changes

Any failure at sea can lead to safety risks, downtime, and expensive repairs. That’s why marine components must not only work well but also meet strict quality standards.

How Investment Casting Helps Marine Engineering

Investment casting solves many of the challenges faced in marine engineering. Here’s how:

1. High Precision and Detail

In marine structures there are various parts like pump impellers and valve housings which have complex shapes. Investment casting makes it possible to produce these parts with tolerance without missing out on fine details.

2. Corrosion Resistance

Investment casting process offers great flexibility in terms of alloys, which protect the marine structures from corrosion due to navigating in seawaters frequently.

3. Strength and Durability

Parts made through investment casting are strong and durable. They can handle high pressure, impacts, and long-term use.

4. Consistency in Production

Investment casting helps in providing consistent quality across batches, which is important for industries like shipbuilding where parts need to be accessed variably.

We have variety of Marine approvals as well as production experience.

Austin Alloy Cast is well-equipped to serve the marine and offshore industries with both extensive production experience and a wide range of internationally recognized marine approvals. Our credentials include certifications from DNV-GL, Lloyd’s Register (LR), ABS (American Bureau of Shipping), Bureau Veritas, and compliance with NORSOK M-630 standards. These approvals reflect our commitment to quality, safety, and performance in challenging marine environments. Backed by years of hands-on manufacturing expertise, we consistently deliver cast components that meet the highest industry standards and customer expectations worldwide.

Looking Ahead

The marine industry is moving toward energy efficiency, lightweight materials, and sustainability. Investment casting supports this progress by enabling:

• Use of lighter, stronger materials

• Fewer welds and joints by integrating parts

• More efficient shapes for better performance

As safety and environmental regulations become stricter, only the most reliable and precisely made parts will be accepted. Investment casting is well-suited to meet these needs now and in the future.

Conclusion

Investment casting is a vital process for the marine sector. It creates strong, detailed, and corrosion-resistant components that meet strict performance and quality standards. With growing demands and advanced marine technologies, investment casting will continue to play a key role—setting new benchmarks for quality, reliability, and performance at sea.

Apart from marine engineering, investment casting specifically rendered by Austin alloy cast is significant since it is suited to smaller and more precise designs which help to incorporate insignia such as logos, Product id and numbers on a surface which helps in brand identification. This is different from sand casting in which moulds are fragmented in order to divest the pattern which does not give the same effect.

To have a glimpse at our world class facility and products, visit us at www.austinalloycast.com.

For any queries or details contact us at info@austinalloycast.com.