Each casting carries a narrative, a story of design, metallurgical achievement, and accuracy of execution. At Austin Alloy Cast Pvt. Ltd., we don’t just produce castings, we create engineering solutions to satisfy the most demanding requirements of our customers. The journey of custom casting consists of collaboration, creativity and quality. A process we have honed over the past 25 years, to guarantee that every piece we produce stands for the finest in performance and precision.

From the first digital blueprint to the last machined finish, every phase of our casting journey displays our skill set, advanced technology and dedication to excellence.

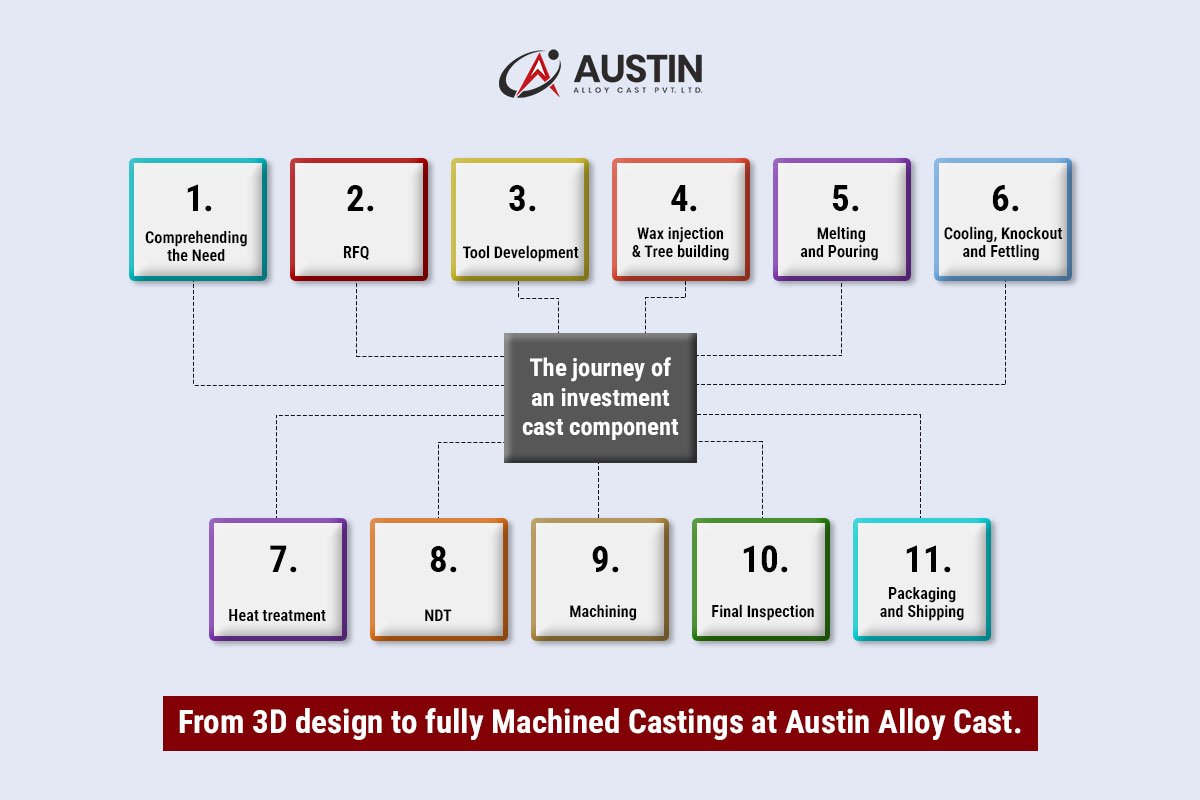

At Austin Alloy Cast investment casting process goes through below stages:

Step 1: Comprehending the Need

All journeys begin with an understanding. No casting is the same as another casting. Each has specific dimensional standards, specific strength requirements, and other application considerations. At Austin Alloy Cast, our process starts with a dedicated discussion with the design or engineering team from our client. We take time to analyze and understand the application, environment, points of stress, and performance expectations.

By working collaboratively, we outline and define the very first inputs from alloy selection to tolerance specifications before the design work ever begins. Establishing this baseline starts the process of maintaining precision through to the end of the process.

Stage 2: Concept and 3D Design

After finalizing the customer’s design, our engineers take those concepts to create them digitally, using advanced 3D simulation software. This 3D design is more than just an image; it is a functional simulation that assesses metal flow to verify our methoding, factors like shrinkage and the distribution of stresses within the design, before the first mold is cut. The 3D design features provide an action plan to improve gating systems, yield and reduce wastage of metal. Everything just to provide cost effective solution to customers.

Additionally, it is the 3D design stage where we at Austin Alloy Cast begin to combine practicality and innovation. Utilizing CAD, pattern simulation and other tools, our engineering team can develop highly precise representations allowing customers to visualized the designed end component. These CAD representations allow for the change of designs at this stage proving cost and time savings from expensive physical iterations later on.

Stage 3: Tool Development with Precision

The next step is where design literally meets function tool making. The die is the basis of the casting, it’s what defines the dimensions and shape of the end product.

Tool development is an outsourced activity at Austin. We propose to our customer manual or automatic tooling based on the volume requirements. Using CNC machining technology, we make high quality patterns using wood, metal, or aluminium. Each is customized to suit the size, complexity, and production run of the casting. That ensures greater dimensional accuracy and repeatability that is required to maintain quality of the final pieces in large production runs.

The pattern development process is closely monitored by our experienced pattern makers and design engineers who collaborate to ensure the pattern matches the approved 3D model.

Stage 4: Wax injection & Tree building

Once the pattern is completed, we move to molding. Our team employs the right molding techniques to generate a cavity that captures the design of the component, depending on the desired alloy and design specifics.

Through complex internal geometries we manufacture precise sand cores that shape the inner cavities of the casting. These cores are made from high performance bonding materials to maintain their rigidity under high temperatures while keeping precise control of dimensions.

Stage 5: Melting and Pouring

Welcome to the realm of metallurgy and accuracy. During this phase, an alloy is melted in a controlled environment, whether it be stainless steel, or carbon steel, or a unique alloy. Chemical composition and melting temperature are monitored within strict parameters to produce a material that adheres to the customer’s specifications.

Every step is carried out within Austin Alloy Cast’s internal safety and quality control protocols, ensuring both operator safety and metallurgical excellence. The result is a precisely cast component that meets rigorous international standards of durability and performance.

For each melt, a heat record is kept on the charge composition, furnace number, melt time, pouring temperature, and deoxidation additions. These records serve as a means of traceable documents to assure processes are repeatable and materials conform to production batches.

Prior to pouring metal, the ceramic shell mold is coated with a predetermined number of primary and secondary coats under strictly controlled temperature and humidity conditions. It is important to control the ambient conditions as they avoid dimensional changes to the wax pattern and avoid cracking or distortion of the shell. The number of coats is dictated by the geometry of the casting, surface area, and in total weight, to provide optimum shell permeability and mechanical strength for the solidification of liquid metal and flowing into a mold cavity.

Stage 6: Cooling, Knockout, and Fettling

Once the molten metal is solidified in the mold, the casting is allowed to cool on its own before the mold is broken open. The result is a rough shape of the part and is still a perfect shape.

We perform shakeout operations to remove the sand and then continue to fettling to cut off any excess metal or risers. This stage prepares the casting for finishing and machining in the ground state to ensure the surface is smooth and free of defects.

Step 7: Heat treatment

For specific alloy requirements or application reasons, castings are heat treated to enhance mechanical properties, including toughness, strength, and ductility. We have an in house heat treating facility that allows for uniform heating and controlled cooling cycles, achieving the best possible performance to the original material.

Once the heat treat is complete, the casting is sand blasted or shot blasted to clean the surface, which is another important operation that leads to the smooth texture and finish desired by our customers. These operations are performed using automated systems to ensure consistency from batch to batch.

Stage 8: Non Destructive Testing (NDT)

Non Destructive Testing (NDT) forms an essential stage in the investment casting process, ensuring the detection of surface and subsurface discontinuities without impairing the integrity of the casting. At this stage, components undergo a series of standardized NDT evaluations to verify compliance with mechanical integrity and customer specific acceptance criteria.

The selection of NDT methods is determined by casting material, geometry, criticality of the application, and defect sensitivity requirements.

Stage 9: Machining

Prior to leaving our facility, every casting is subjected to extensive examination and testing. Our quality assurance department performs Non Destructive Tests, dimensional inspections, and chemical mechanical testing and inspections to confirm every product meets the international standards.

We believe quality is developed, not inspected. Therefore, we document and monitor each step of the manufacturing process. From spectroscopic analysis through to the radiograph inspection, our team works to assure that the final casting meets or exceeds expectations.

Step 10: Final Inspection

In the final inspection stage, each casting undergoes thorough visual and dimensional verification to ensure compliance with customer specifications and quality standards. Visual inspection identifies surface defects such as cracks, laps, or inclusions, while dimensional accuracy is confirmed using precision instruments like CMM, Vernier calipers, micrometers, height gauges, and dedicated fixtures. Measurements are taken against approved drawings and CAD models, ensuring tight tolerances and geometric accuracy. All inspection tools are periodically calibrated to maintain measurement reliability. Inspection findings are documented in the Final Inspection Report, ensuring full traceability, quality conformity, and approval before the casting is cleared for packing and dispatch.

We believe quality is developed, not inspected. Therefore, we document and monitor each step of the manufacturing process. From spectroscopic analysis through to the radiograph inspection, our team works to assure that the final casting meets or exceeds expectations.

Stage 11: Packaging and Shipping

The last stop on the casting journey is packaging and shipping. We recognize the importance of protecting our products during delivery, and we use specially designed packaging to protect them from corrosion, abrasion, and deformation. All shipments from Austin Alloy Cast come with degree inspection and test reports to demonstrate our transparency and reliability.

A Heritage of Accuracy and Reliability

Each casting produced here at Austin Alloy Cast is the culmination of our human skills, technology, and unwavering commitment to quality. From the RFQ stage through to the fully machined casting, each step of the process reflects the love we have for achieving perfect outcomes, while enhancing customer satisfaction.

Our commitment to our customers is to do just that make their every concept a high performing reality. The journey from concept to metal can be a long one, however, at Austin Alloy Cast we have the ability, the world’s most advanced facility and a strong commitment to quality, allowing us to define and deliver every custom casting project to excellence, in movement.

To have a glimpse at our world class facility and products, visit us at www.austinalloycast.com.

For any queries or details contact us at info@austinalloycast.com.