Investment casting is a 6000 years old process which is still being used in evolved form by industries worldwide. The parts manufactured by this process have a wide variety of applications ranging from basic and simple products like door handles to auto parts and complex components of industrial machinery. Wherever you see metal components with perfect finishing, no wonder it might be made using the investment cast process.

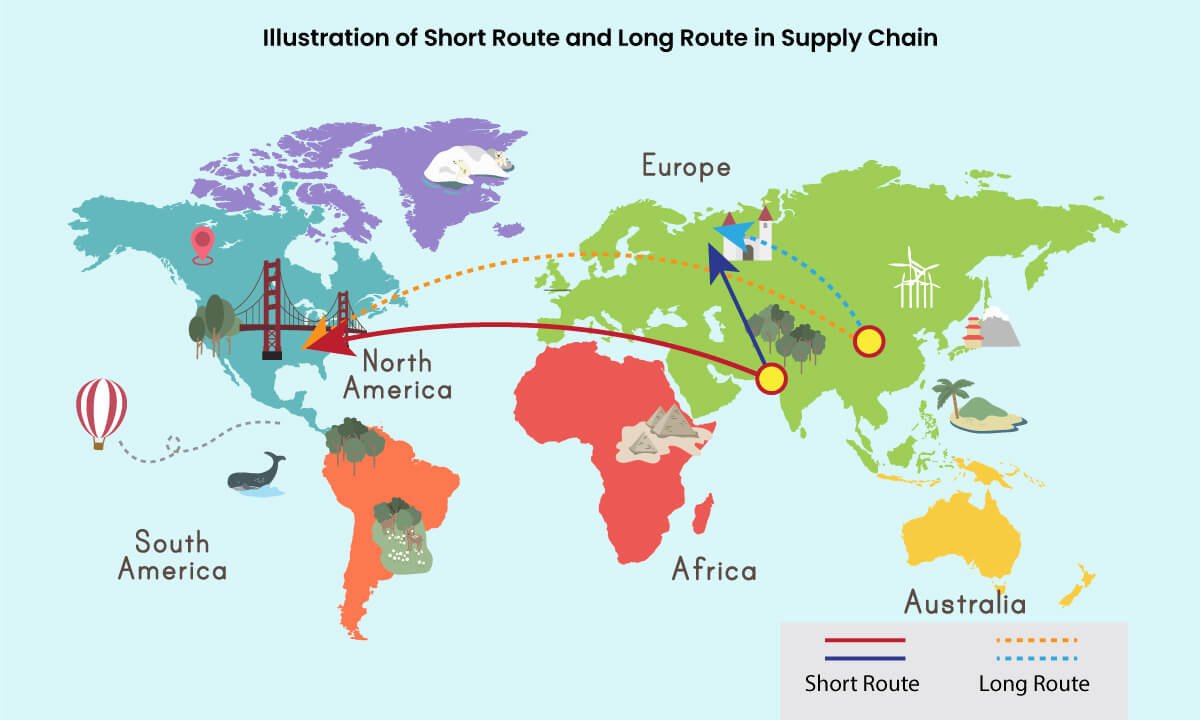

Investment casting process can achieve accurate design with consistency and repeatability. Therefore there are investment casting manufacturers scattered across the globe. Initially investment casters were concentrated in North America and Europe but over time globalisation opened up doors to low cost country (LCC) sourcing.

Like every other industry affected by the pandemic, the investment casting supply chain also faced issues due to increased processing time at ports. This led to higher lead time, higher inventory carrying cost and disrupted production schedule. Depending on a single country for all your investment casting requirements turned out to be a less resilient supply chain. Supply chain diversity by dual country sourcing is now the solution. Sourcing the manufacturing process from reliable countries like

India’s favourable and stable economic policy is making it a reliable sourcing destination for global companies.

Austin Alloy Cast’s commitments towards unmatched customer service by CONSISTENT Quality and EXCEPTIONAL Delivery Performance is making us a preferred partner in the investment casting manufacturing value chain.

With the current ongoing situation of Trade War between countries, the scenario is less likely to improve in the short term. Western companies are increasingly trying to reduce dependency on China sourcing. Meanwhile, Russia-Ukraine conflict has led to rising power costs across Europe forcing foundries and forge shops to cut production. Amidst all the uncertainties, India is turning out to be a favourable sourcing destination for investment cast components requirements.

India has the manufacturing eco-system to fulfil this supply chain void. Indian investment casting houses can simplify your supply chain by delivering fully finished and ready to use components.

Globalisation opened doors to best cost countries (BCC) sourcing but along with it came logistical risks. Covid-19 cracked open the fault lines of global trade. A purchasing manager well aware about these risks would mitigate it by creating a dual sourcing strategy.

As for the investment casting industry, India can be the best alternative route for the supplies of components. Be it oil and gas, food processing, heavy and earth moving equipment, marine and general engineering, India investment casters have capability to supply high volume components as well as castings upto 150 kgs weight per piece.

North American buyers of investment casting can realise significant cost savings bypassing the high tariff rates levied on Chinese imports. India has the capability to fill this vacuum.

To sum it up, India will emerge as the investment castings manufacturing hub. Look no further than Austin Alloy Cast for high quality cost effective investment casting solutions. With one of the largest manufacturing facilities at a single location in India we are ready to serve you.

To have a glimpse at our world class facility and products, visit us at www.austinalloycast.com.

For any queries or details contact us at info@austinalloycast.com.